Welcome friends! This post is numero uno in a series of three we’re putting together to give you the lowdown on the three main shipping options out there: cardboard boxes, wooden crates and reusable cases. I’m sure you can figure out which of the three is our favorite. But what you might not know is that there are some great reasons behind our love for reusable cases, and they go way beyond our own business interests!

So, without further ado, here’s the (sort of) good, the bad and the ugly on shipping with cardboard boxes.

The (Sort Of) Good

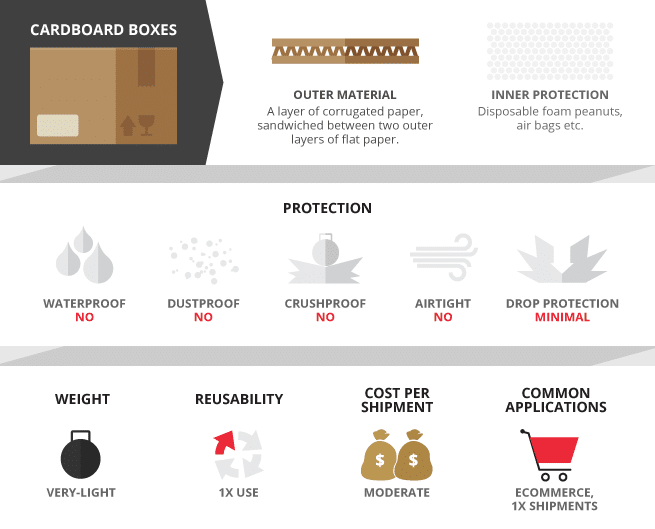

There’s no arguing it: When it comes to weight alone, cardboard boxes are lightest of the three. They can

also be handy for one-time shipments. However, this pro is growing weaker by the moment. More and more companies are switching to a more sustainable practice, sending one-off shipments in reusable

containers that are then returned to the company by the customer.

The Bad

Providing protection is a serious weakness for cardboard boxes. They’re easy to crush and offer very little protection against drops and vibrations. Also, air, dust and moisture have no problems passing through cardboard, which puts things like electronics at high risk of environmental damage during shipping. You might be thinking, yeah, that’s all true, but 99% of the carboard box shipments I receive arrive just fine. And you’re right. However, what most folks don’t realize is how much product is damaged during shipping every year from a big-picture perspective (that is, including bulk shipments and so on). The cost to businesses and to the environment due to shipping damages is astronomical.

The Ugly

Speaking of the environment, here’s where things get certifiably ugly when it comes to cardboard box shipping. In 2014, 35.4 million tons of cardboard were produced in the United States. A large percentage of that waste is attributed to the bustling ecommerce industry, where unsustainable practices like nesting smaller boxes within larger boxes to provide protection are rampant. And the trees aren’t the only resource taking a hard hit. The cardboard manufacturing process includes a practice called “pulping,” which produces a moldable solution. Unfortunately, this highly moldable solution comes at the cost of lots and lots of wasted water.

So, there you have it. We wish we could say nicer things about cardboard shipping boxes, but, even if we weren’t in the reusable shipping case business, we simply couldn’t. Thanks for reading! Be sure to check back soon for Part 2, where we’ll give you the lowdown on wooden crates.

Check Out More From Custom Case Group:

Shipping Fragile Items – A Cheat Sheet

Top 5 Mistakes to Avoid When Picking a Custom Case

‘Custom ATA Cases’ – What They Are & Why You Need Them

![Superbowl Trophy[6]](https://customcasegroup.com/wp-content/uploads/2024/04/Superbowl-Trophy6-e1713197189995.jpg)