Why Custom Cases?

Where We Started and How We Got to Where We Are

When you work with us at Custom Case Group, you’re working with a combination of two of the leading custom case providers in the country: SCS and EPS. Working together to create custom cases, we are proud to offer unmatched services, products, and solutions across multiple industries.

Sales Coverage Map

Customers across the United States and around the globe have come to recognize our team at Custom Case Group as an industry leader in the field of custom cases. For protection and security when transporting your sensitive equipment in challenging environments and under harsh conditions, we are here to provide solutions.

Founded in 1992, Engineered Packaging Solutions engineers custom cases for customers throughout the Western United States. Based in San Dimas, California, EPS’s manufacturing facility contains state-of-the-art water jet machines, steel rule die presses, and CAD/CAM technologies to provide consistent, accurate foam cushion inserts.

SCS Cases has been engineering custom cases since 1976. The company’s home office is located in Chicago, Illinois, and uses the latest water jet, routered, FlashCut CNC, steel rule foam cutting, and CAD/CAM case design technologies. SCS proudly serves customers throughout the Midwest, East Coast, and Southeast regions of the United States.

Sustainability now — paving the way for a better world tomorrow.

At Custom Case Group, maintaining our environment and safeguarding the planet for future generations is a part of everything we do. Throughout our process, we strive to utilize sustainably sourced materials for production and our daily operations. We are constantly looking for new ways to streamline our operation to implement even higher levels of sustainability in the future. Leaving a legacy of sustainability and responsibility has been — and always will be — a pillar of our company.

We are proud to partner with our customers to not only engineer custom cases for use in a variety of applications and industries but also serve the needs of our environment. This responsibility plays a significant role in our daily decisions, the materials we use for production, and the processes we use throughout our business. Reach out to us today to learn more about our commitment to sustainability, how it affects the products we provide, and what it could mean for you as a customer.

Capabilities

We provide cases for a wide range of industries, from healthcare to aerospace, and meet MIL-SPECS and other standards.

CNC Router

Our steel die cutting machines create precise and accurate foam interior inserts shaped to fit your equipment.

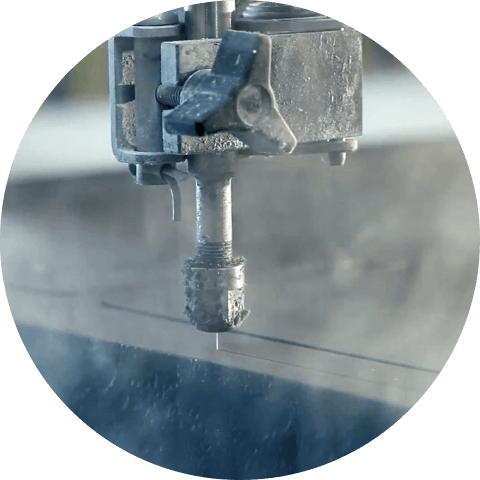

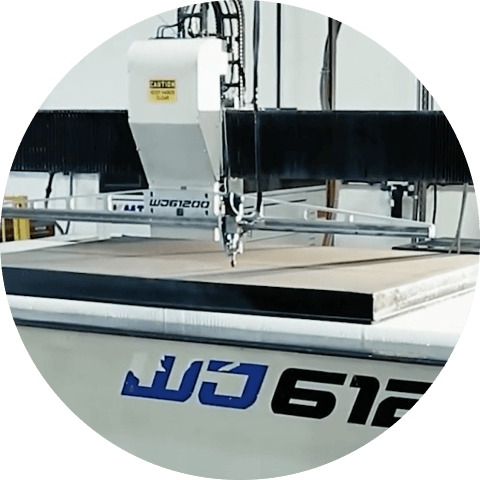

WaterJet Cutting

Our waterjet cutting machines create intricate, precise designs in order to reduce our product lead times.

Flashcut CNC Machine

Our FlashCut CNC machines can offer ultimate control in precision cutting for use in a variety of applications.

CAD/CAM Software

By using CAD/CAM software, we have the capability to take your concept from design to production seamlessly.

When you call us at Custom Case Group, we can help you choose the type of case that best suits your application — plastic, aluminum, or wood/composite. Our design staff uses a variety of materials and methods, including rotational molding, injection molding, blow molding, formed aluminum, and plywood fabrication to construct your case.

Our cases come in a variety of sizes and dimensions, so whether you’re looking for a lightweight, portable case or a heavy-duty shipping case, we’ve got what you need. We can customize the features of any case to provide you with a solution for any specific requirements. Some of our customizations have included designing exterior ports for electronic connections and installing cooling fans to keep the case contents operational with the case lid closed.

Our team uses the latest, state-of-the-art equipment and technology to provide you with your custom case.

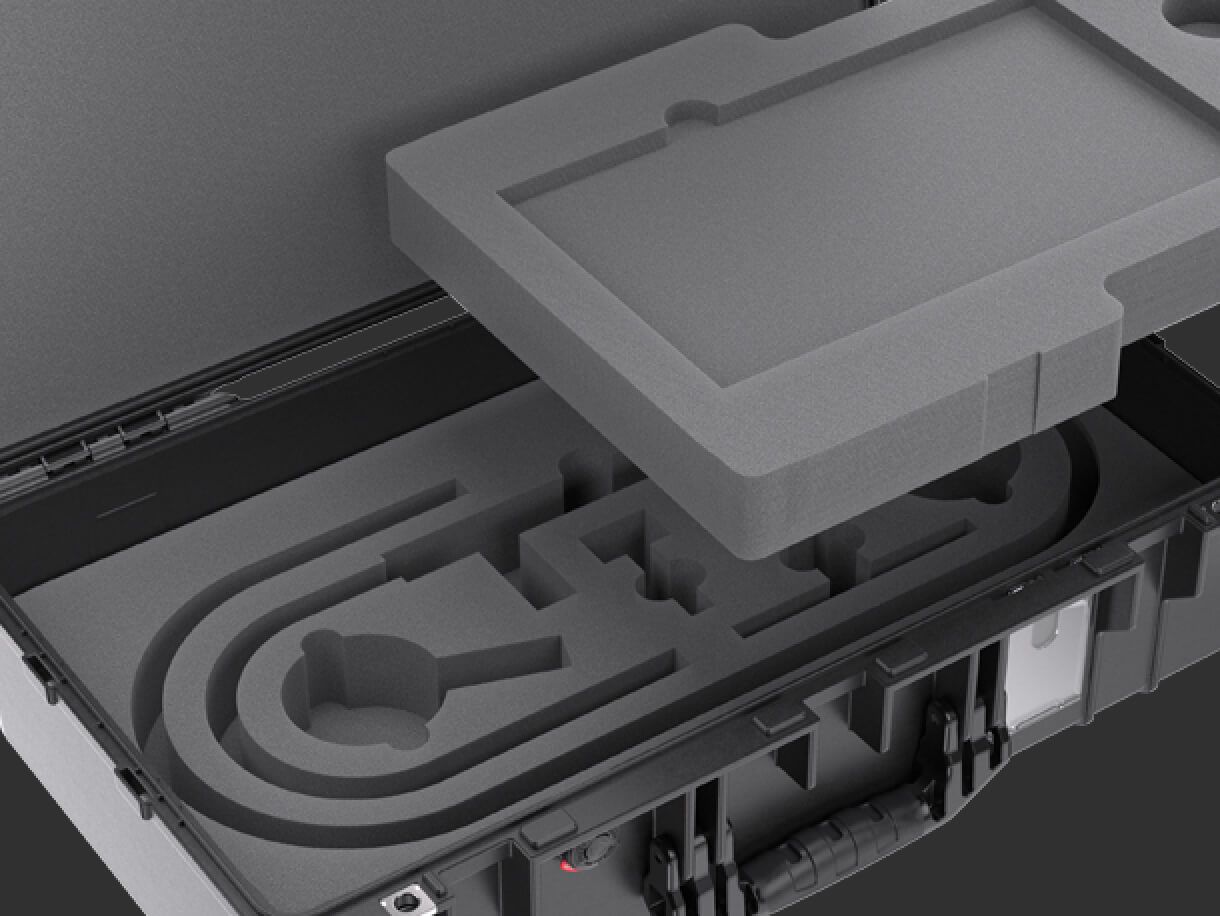

Our custom foam inserts ensure that your valuable equipment is protected and secure under any conditions. Our engineers use foam-fabricating equipment, including steel die cutting, waterjet cutting, router and FlashCut CNC machines, and CAD/CAM software to customize your case interiors. This technology allows us to construct the type of foam you need as well as cut the foam to your specifications.

For more information and a look into our case studies, contact us today.

Certifications

At Custom Case Group, we follow the standards of ISO 9001:2015 and AS9120B, and are certified for both.

ISO 9001:2015

Guidelines for auditing a quality management system developed by the International Organization for Standardization.

SAE AS9101D

Checklist of Aerospace Quality Standards established by the Society of Automotive Engineers International.

AS9120B

Certification for the quality management system with a customer focus, top management involvement, a standard approach to process, and continual improvement.

TESTING FOR CERTIFICATIONS

Sometimes our custom cases must pass muster for the different industries in which they will be applied. At EPS and SCS, we do a number of tests to ensure that your custom case is shockproof, waterproof, or dustproof; or meets other specific industry standards.

Some of the common certifications for custom cases include:

- P67

- IP66

- Def Stan 81-41/STANAG

- 4280

- MIL C-4150J

- IP57

- ATA 300

- IP65

- MIL-STD 810H

- ASTM D775 – Drop

- ASTM D951 – Water

- Resistance

- ASTM D999 – Vibration

- FED-STD-101C