Introduction to Impact

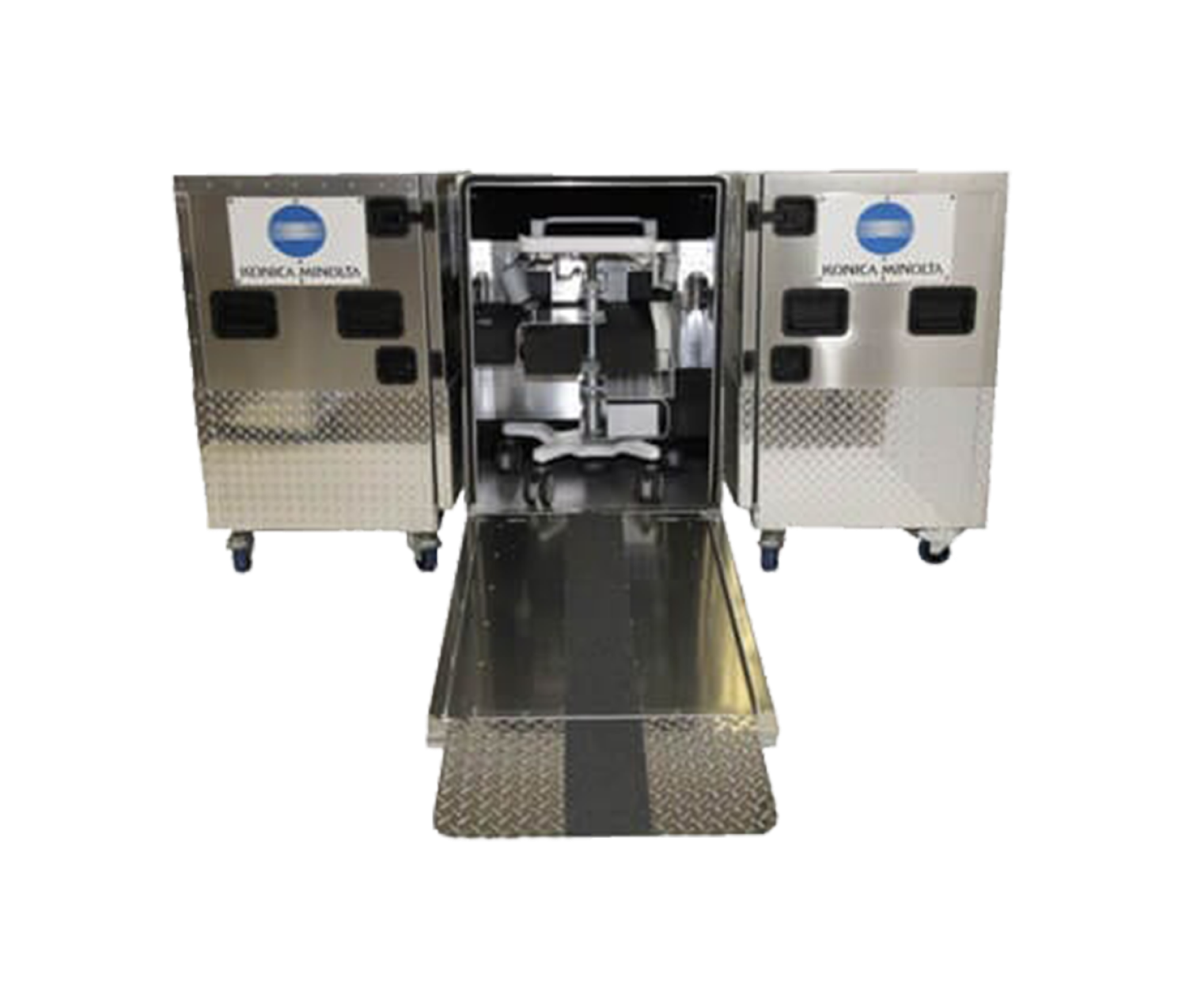

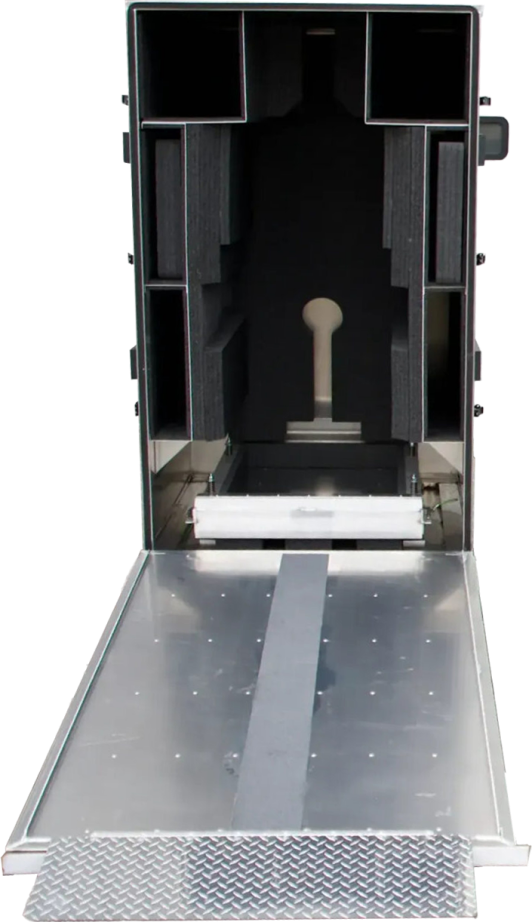

Impact custom cases go far beyond the status quo to set new standards in functionality and durability.

Aluminum cases are lighter, stronger, and more cost-effective. A protective aluminum case from Impact is reusable, reparable, highly customizable, and completely recyclable. Unlike other shipping container materials such as polymers and plastics, a custom aluminum case design is not beholden to any previous mold or fixture — each Impact case is truly unique.

Cases

Case styles for every use

We offer cases of all sizes, ranging from personal micro cases to large cases designed to secure on top of a vehicle cargo carrier.

Single-Lid

Any size, any quantity. Many of these containers incorporate custom foam interiors or hard mount options.

Military

Pelican Hardigg military cases can stand up to transport in the harshest environments in the world.