Built For You.

Our cases ensure the safety of your products when shipped anywhere in the world.

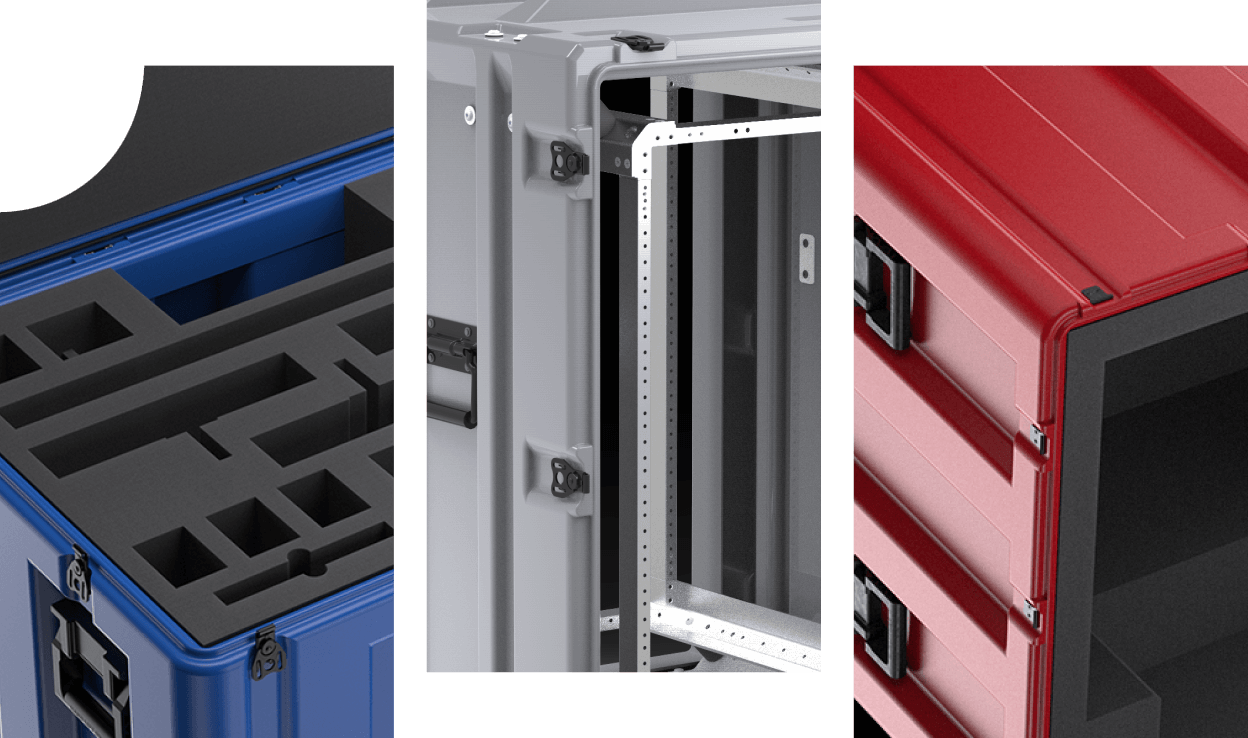

Featured cases now available in store

Rack Mount Cases

Purchase or get a quote

A leader in the reusable case industry, Pelican cases are sunonymous with quality.

Introduction

In 1995, two of the premier case companies joined forces to become the go-to destination for custom protective cases across a wide range of industries.

Industries

Customized protection in any environment

From oil rigs to battlefields, convention centers to shipping hubs, our cases protect mission-critical gear around the globe.

Client:

Defense Contractor

Client:

Defense Contractor

Success Stories

Military Aerospace Equipment Case

This custom case allows a critical system for a major military combat vehicle to be transported safely and dependably in some of the world’s most extreme environments.

Success Stories

Military Combat Vehicle Component Case

This custom case allows a critical system for a major military combat vehicle to be transported safely and dependably in some of the world’s most extreme environments.

How It Works

See how we build cases you can trust

Our cases offer the highest level of protection in the harshest conditions with fully customizable options to suit your unique needs.

Sustainability

Our products are made from sustainably sourced materials.

Contact Us

Learn how our cases can meet your needs

Pelican, the maker of battle-proven protection pieces, has engineered the ultimate drone transport cases. Now you can travel through grab trucks, airports, construction sites, action packed movie sets and more with your fully outfitted drone intact.