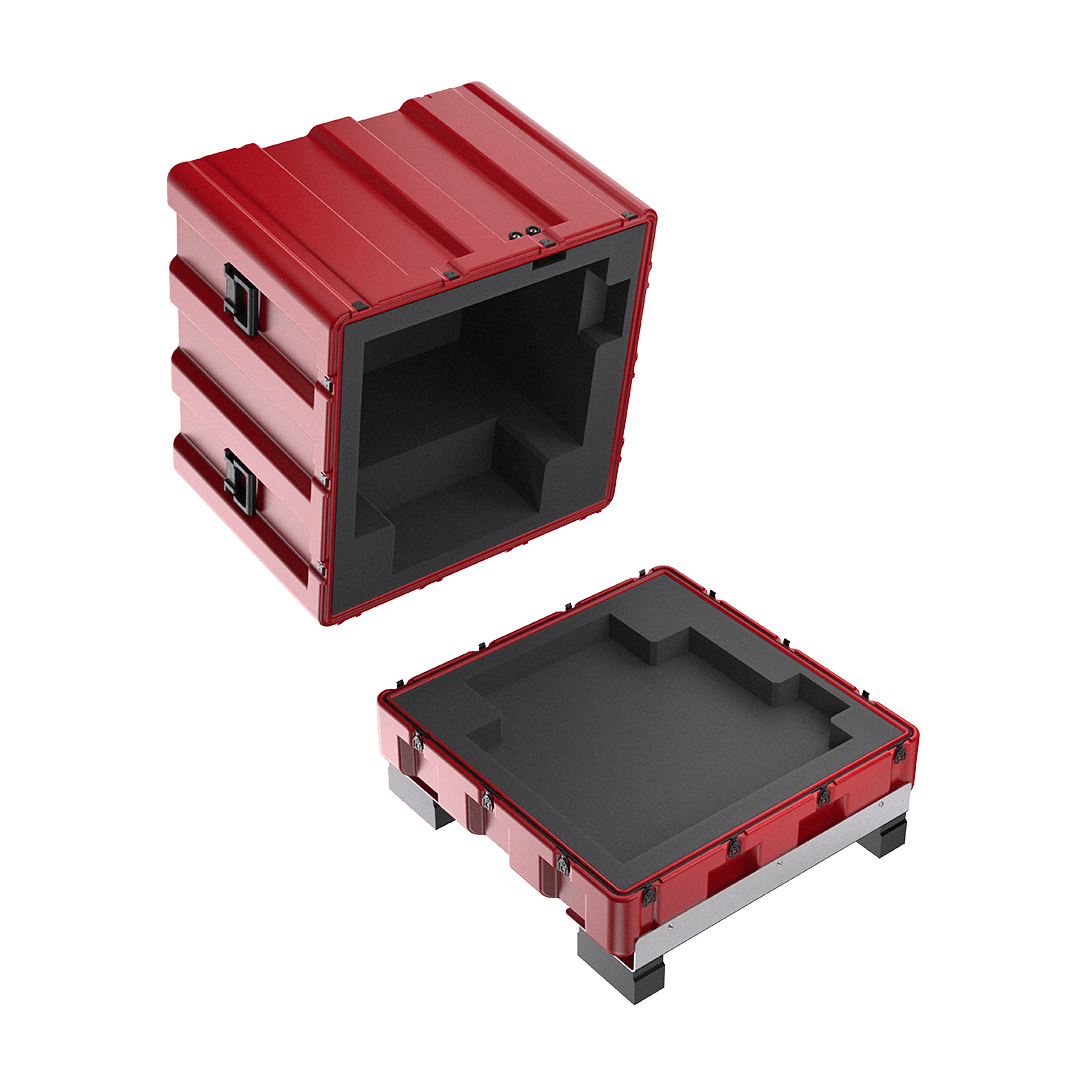

Single-Lid Case

Description

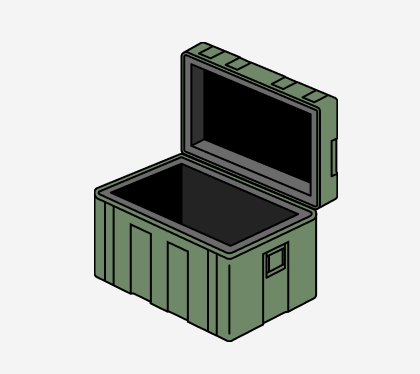

Pelican-Hardigg single-lid cases can be tested to be waterproof, dustproof, chemically resistant, and shockproof.

Pelican-Hardigg single-lid cases are built to withstand the most severe conditions. Each case is rotationally molded with corners and edges 10–20% thicker than the walls to provide strength where it’s needed most. The case is one piece, with anti-shear locks connecting the base to the lid. The tough outer shell of polyethylene retains its shape despite rough handling. Molded-in metal components and recessed latches and hinges are protected from damage.

With field life expectancies of 10 years or more, these cases reduce replacement costs and downtime. Pelican-Hardigg single-lid cases also have lower shipping costs and can be easily stacked for transport. At Custom Case Group, we provide Pelican-Hardigg single-lid cases that are customized to protect your sensitive equipment and meet your unique needs.

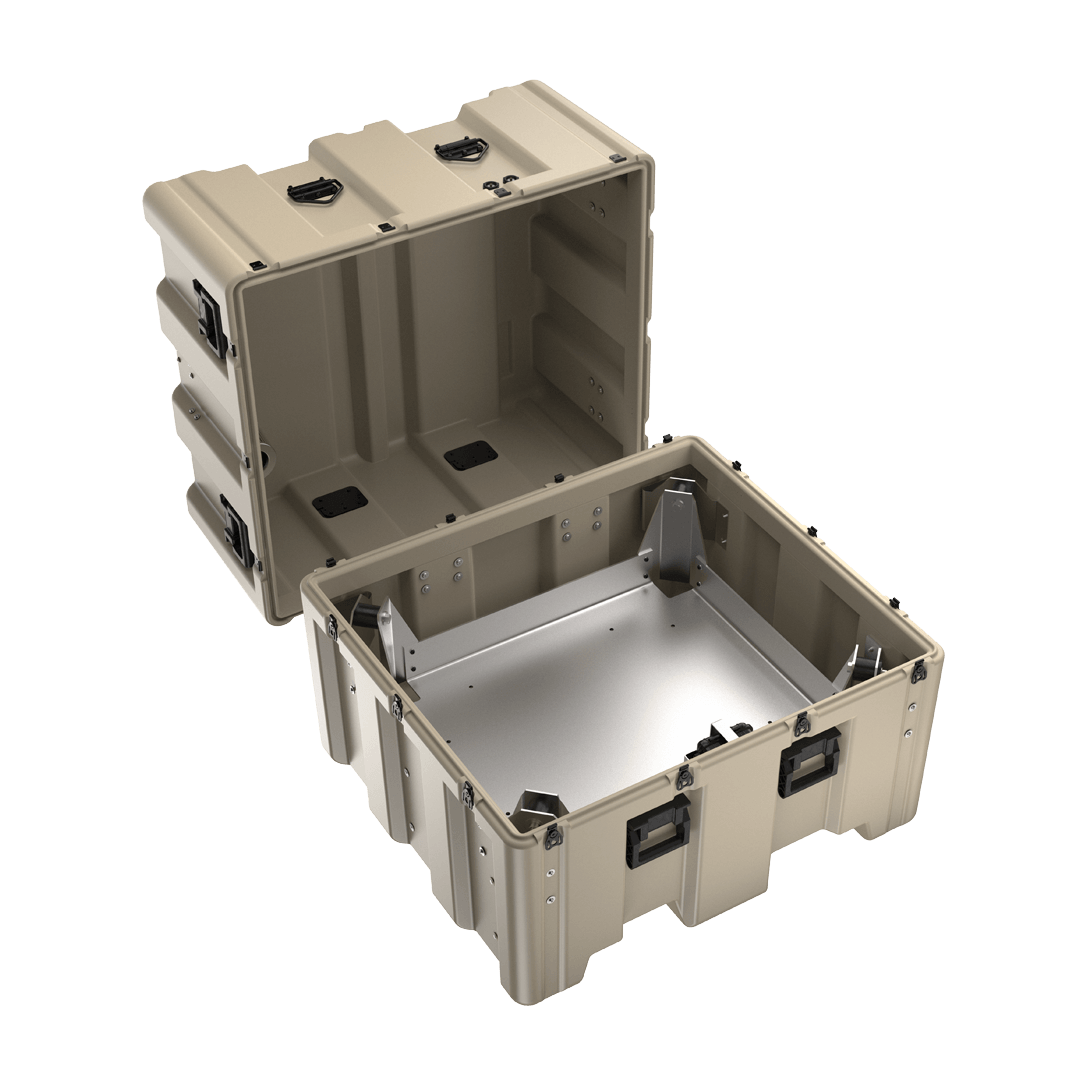

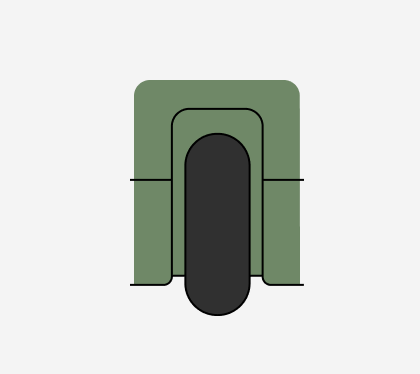

Anatomy

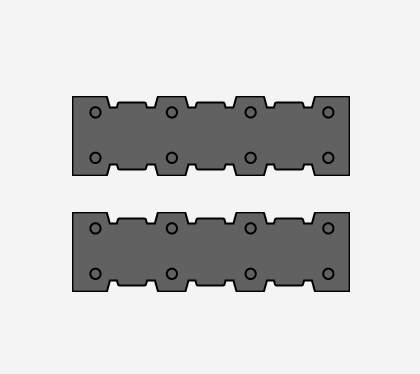

- MOLDED-IN STACKING RIBS – Secure non-slip stacking on matched size cases.

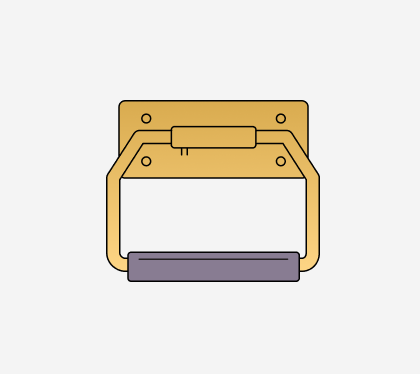

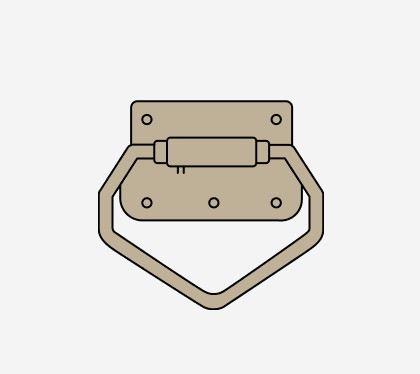

- COMFORT GRIP HANDLES – A Pelican-Hardigg patented feature, heavy-duty, spring-loaded to lie flat.

- PATENTED MOLDED-IN METAL INSERTS – Catch & hinge attachment points designed to distribute the load to case walls.

- DOUBLE-LAYERED, SOFT-GRIP HANDLES – Tested and proven strong, these comfort grips are made to withstand heavy loads.

- RECESSED HARDWARE – Hardware protected from impact, snag-free transport.

- DOUBLE WALLED RIM FOR TONGUE-IN-GROOVE SEAL – Remains sealed after impact; splash and rain resistant; air and watertight options.

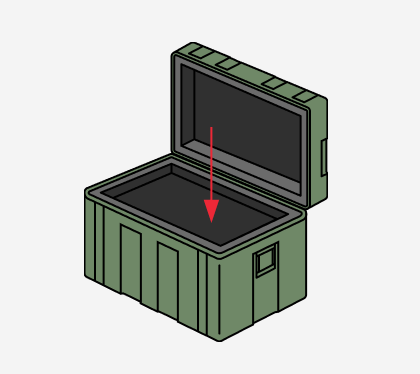

- POSITIVE ANTI-SHEAR LOCKS – Prevent sid separation upon impact, minimizing hardware stress.

- REINFORCED CORNERS & EDGES – Thicker corners and edges for added impact protection.

Certifications

Pelican-Hardigg Military Cases are designed to meet the following certifications. The Custom Case Group can test and certify for additional certifications to meet your requirements.

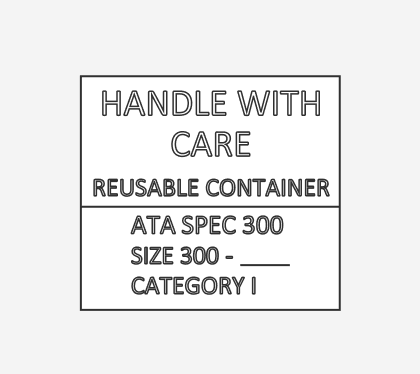

ATA Specification 300, Category 1300

MIL-STD-810

Common Pelican-Hardigg Case Customizations

- Custom Case Sizes (350)

- Custom Foam Cushioning

- MIL-SPECS

- Temperature-Controlled Interiors

- Shock Suspension Systems

- HAZMAT

- Case Lid Configurations

- Extra Handles / Telescopic Handles

- Locks & Hasps

- Casters

- Purge Valves / Fill Valves

- Airtight/Watertight/Humidity Indicators

- Lifting Rings

- Forklift Skids and Bash Plates

- Card Holder

- Custom Hardware

- ID Plates

- Labels & Stenciling

- Colors

- Cut-and-Weld

Single-Lid Case Customization Options

At Custom Case Group, we are ready to customize your Pelican-Hardigg single-lid cases to meet your specific requirements.

Base Configuration

Additional Charge

Select Options

Hardware

ZINC YELLOW

ZINC BLACK

STAINLESS STEEL

STAINLESS STEEL BLACK

Handle

ZINC YELLOW

ZINC BLACK

Comfort grip plastic

STAINLESS STEEL PASSIVATE

STAINLESS STEEL BLACK

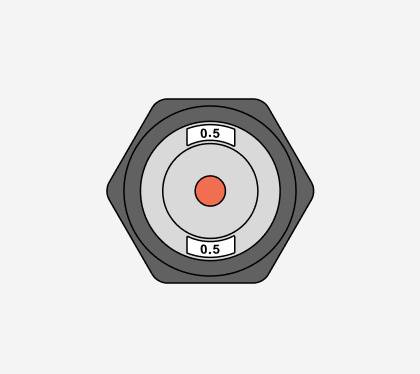

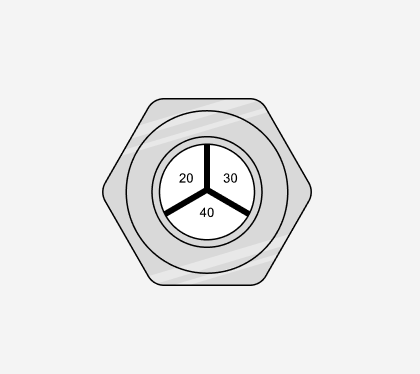

PRESSURE RELIEF AND HUMIDITY

FREE BREATHING

Closed gasket with Prv

AIRTight certified

humidity indicator

ROLLING FEATURES

edge caster 1

edge caster 2

bottom casters

T-handle with Bumper

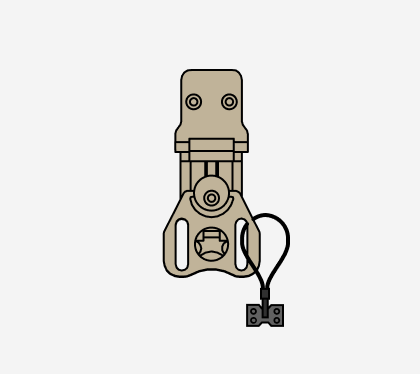

SECURITY FEATURES

lockable cable catch

padlock hasp

CARDS AND LABELS

card holders

ID PLATE

FRONT LABEL

ATA/STD LABELS

LIFTING FEATURES

LIFTING RINGS ZINC YELLOW

STAINLESS STEEL PASSIVATE

LIFTING RINGS

SKID RUNNERS

FOAM OPTIONS

FOAM LINED

FOAM FILLED

FOAM LINED AND FILLED

CUSTOM FOAM

ROTO COLORS

STD gray – 133

LW grey – 572

FED std #26270

STD TAN – 250

LW TAN – 587

FED std #20372

BLUE – 135 (lt)

PANTONE #292U

STD WHITE – 132

FED STD# 27925

LW WHITE – 586

STD yellow – 136

LW yellow – 588

pantone #012U

STD green – 138 (forest)

FED std #24052

orange – 134

FED std #12197

STD yellow – 131

LW yellow – 588

Fed std #23538

maroon – 197

pantone #202U

std blue – 101 (DK)

lw blue 585

fed std #25052

std black – 032

LW black – 583

fed std #27040

std red – 130

fed std #21105

std olive drab – 137

lw olive drab – 584

fed std #34096

purple – 129

pantone #245U

Light Lift Cases

Pelican-Hardigg™ Light Lift™ cases combine agility and durability. At up to 30% lighter than our traditional heavy-duty roto mold cases.

- Light Lift cases reduce shipping costs.

- The Pelican-Hardigg™ Light Lift™ series is the most significant advancement of roto molded cases on earth.

- Pelican-Hardigg™ Light Lift cases are available in many of the standard single-lid sizes.

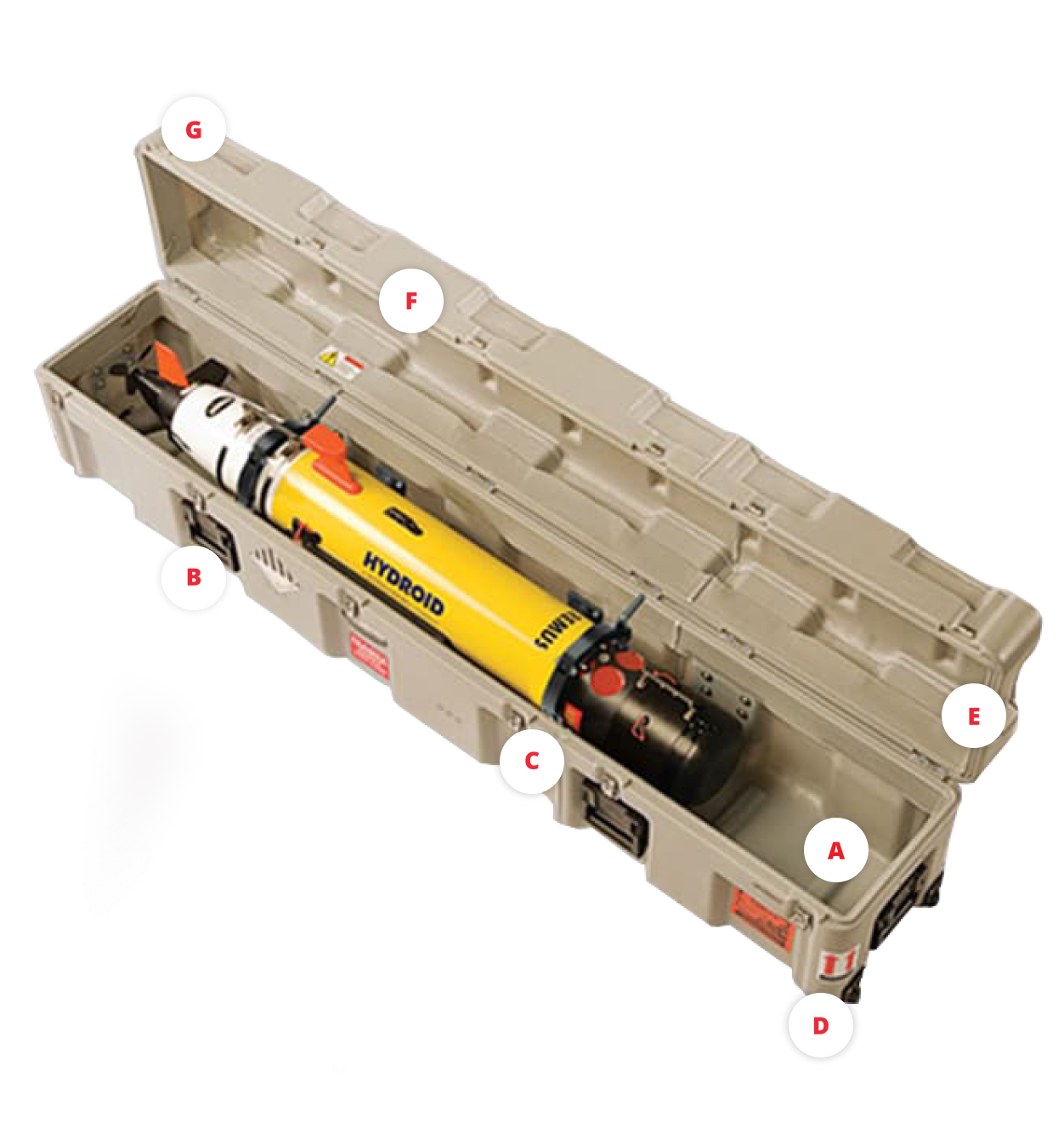

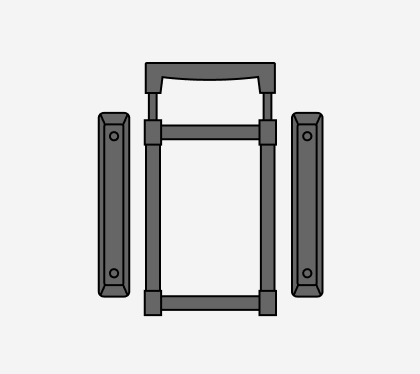

Inter-Stacking Pattern (ISP) Cases

Pelican-Hardigg™ Light Lift™ cases combine agility and durability. At up to 30% lighter than our traditional heavy-duty roto mold cases.

- Six cases that start with “IS”

- IS2117-1103

- IS2917-1103

- IS3721-1103

- IS4517-1103

- IS4521-2303

- IS4537-2303

- Cases cross-stacked like Legos

- Sizes designed for use with:

- 463L pallets

- NATO pallets

- JMIC containers

- Sea containers

- ISP cases pass -40°F (-40°C) drop tests

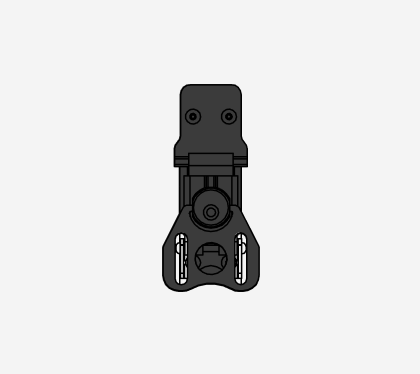

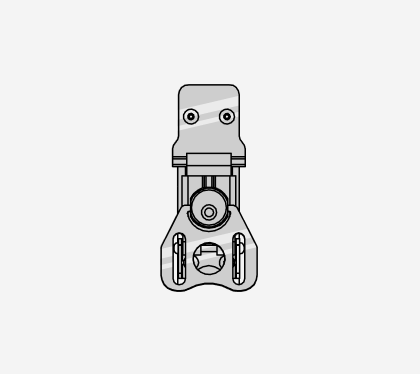

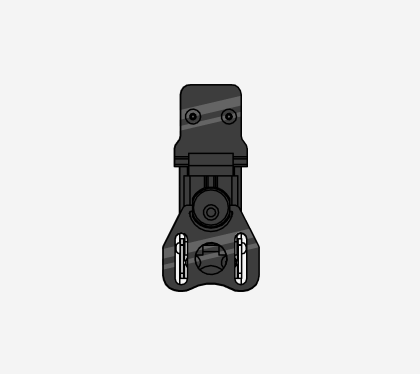

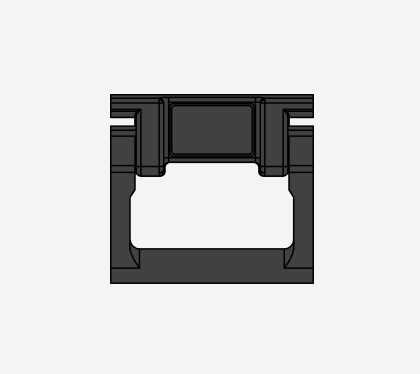

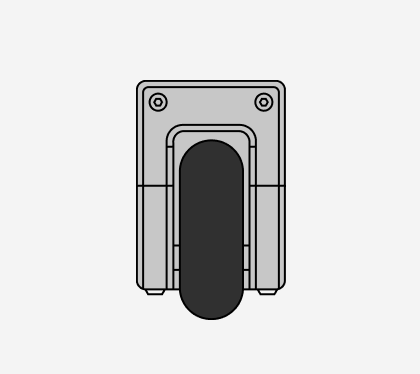

The Anatomy of a Roto Case Body

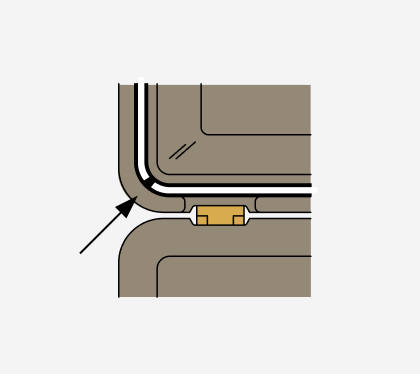

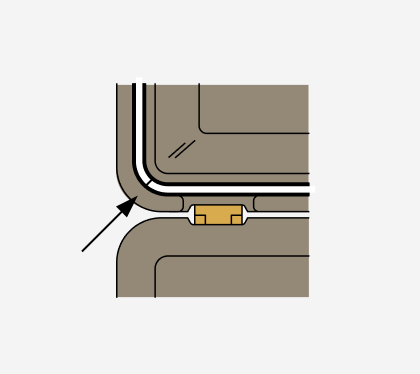

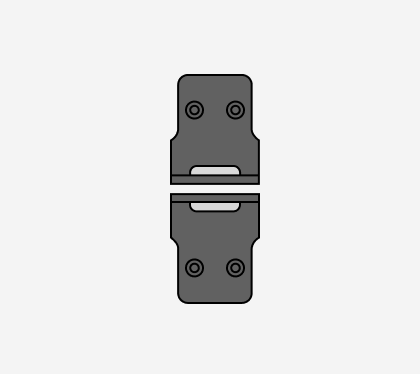

POSITIVE ANTI-SHEAR LOCKS

The anti-shear feature prevents lid separation upon impact and minimizes hardware stress.

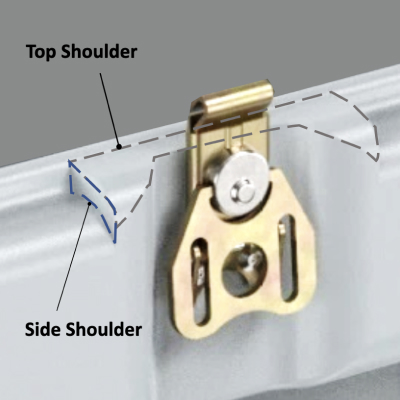

The shoulder of the lid and the base shoulder support the stacked load; therefore, stacking weight is not transferred to the gasket.

RECESSED HARDWARE

The recess in the case protects from impact; snag-free transport.

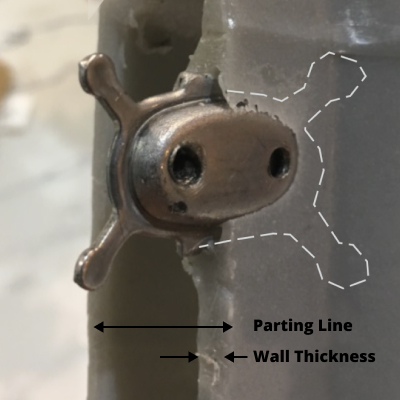

PATENTED MOLDED-IN METAL INSERTS

These are hardware attachment points designed to distribute load to case walls. These are referred to as “bugs.”

Wall Thickness

AL cases = nominal 3/16” (4.76 mm)

BL cases = nominal 1/4“ (6.35 mm)

CL cases = nominal 1/8” (3.175 mm)

Parting Line Thickness

AL = 1.5″ (38 mm)

BL = 2.0″ (51 mm)

CL = 1.0″ (25 mm)

DL = 1.75″ (44 mm)

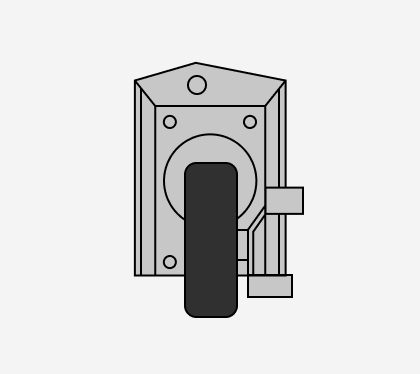

Configurable Case Styles

Standard Single Lid

Reverse Application (RA)

Deck Cases

Flange Mount (FM)

Fork Truck Cases (FT)

Light Lift Cases

ISP Single Lid

Grab and Roll (GR)

Custom Case Materials – Polyethylene (PE)

Description

- Ground to the size of salt

- Pelican’s PE is always virgin PE; contains no fiberglass or carbon fiber

- Lb/resin based on case size and desired wall thickness

- Schedulers group cases based on loading the roto arm

- We can make quantities of 1 or 100+, so there is no MOQ

Finished Case Temperature Range

- Min: -20°F (-29°C)

-40°F (-40°C) requires testing - Max: 140°F ( 60°C)

PE Plastic Facts

- PE is a plastic; its characteristics change with temperature.

- Stiffness, impact strength, and dimensional size vary with temperature.

- Case dimensions vary +/- 2% case to case, on average 3/16” (4.76 mm).

- Larger cases can vary up to 1/2″ (12.7 mm) due to the plant environment.

- The base and lid are run together. The lid and base are set up to cool with the lid and base together, so they cool as a pair.